High speed linear THz camera

High speed linear THz camera

High Speed Linear THz camera is our brand new product, which features both, unprecedented imaging speed of 5000 frames per second and ease of integration into any industrial process. Its ultrafast linear sensor array is built to satisfy the needs in Non- Destructive Testing (NDT) and Quality Control (QC) for many industrial applications employing high speed conveyors belts. This product fits most conveyors with a belt speed up to 15 m/s.

Our Linear Terahertz Imaging System consists of two parts: a terahertz imaging camera and THz generator, both optimized & synchronized to each other. The generator is supplied with a specially configured horn antenna designed to cover the entire imaging area across conveyor belt. The horn spreads THz beam evenly and ensures that the whole THz radiation power is properly delivered from the generator into the camera. The camera pixel size determines image resolution of 1.5 mm, which is more than ample to support imaging in most industrial applications.

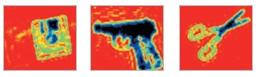

Samples of THz images made by THz

Samples of THz images made by THz

COMPETITIVE ADVANTAGES:

♦ No ionizing radiation

♦ Extremely high image acquisition rate (5kHz)

♦ Ease of integration into industrial process

♦ CE Certification of Compliance

♦ Plug-and-Play design and customized solutions

♦ LOW COSTSPECIFICATIONS

|

Number of pixels: |

.. |

256 (256 x 1) |

Image acquisition rate: |

........ |

5000 fps (5 KHz) |

|

|

Pixel size: |

1.5 x 3 mm |

Responsivity: |

8000 V/W |

|||

|

. |

||||||

|

Imaging area: |

384 x 3 mm |

100 nW (at 5000 fps |

||||

|

Dimensions of device: |

.. |

450 x 160 x 44 mm |

.............. |

Min detectable power/pixel: |

45 nW (at 1000 fps) |

|

|

Sync out: |

TTL (+5 V) |

14 nW ( at 100 fps) |

||||

|

. |

||||||

|

Interface: |

mini-USB |

Software supplied: |

TeraFast® Viewer |

| Rapid non-destructive, non-invasive characterization and imaging of objects / defects in uniform materials or under coated surfaces has never been easier and faster than with our high speed camera codenamed TeraFAST. Its record breaking image acquisition rate opens up doors to many industrial applications associated with Non-destructive testing, quality control and process control. |

| . |

Pharmaceutical and Cosmetics Industries |

....... |

Wood Processing Industry |

| Non-destructive testing (NDT) of drugs, medical products and baby’s diapers at industrial production lines. | Detecting concealed hollows, internal forms, shapes and/or defects saves a lot of time on inspections.Wood analysis - checking wood for water / moisture inside. | |

| . | ||

Food Industry |

FMCG packaging |

|

| Non-invasive technique for monitoring availability / number ofhazel nuts inside of chocolate candy (already wrapped and packaged);detecting any plastic debris, extraneous bodies or inhomogeneous parts (clots) inside ready food products. | Checking availability of items inside packages as a process control step; detecting foreign objects inside packaging meant to exclude human error or defective items inside the package. | |

| . | . | |

Construction Materials and Building Trades |

Automotive Industry |

|

| Use THz imaging camera at manufacturing facilities or at construction sites to find out inhomogeneous elements or moisture in concrete, floor screed, plaster, wall paint etc. | Indentify presence (or absence) of steel objects (viz. wires) or foreign bodies & elements inside of rubber tires.Inspect fitted tires on wheels to identify special run-flat nylon inserts attachedto alloy wheels inside a tire, precluding tiresome tire removal for visual inspection. | |

| . | . | |

Agriculture and Livestock farming |

Security screening and Letter scanning |

|

.Potato selection process running on conveyor belt aimed to separate planting-potatoes from mud clumps and stones. Measure the thickness of a wool coat on a live sheep. |

Homeland security: identification of hidden objects concealed in bags at the airports or check-points.Checking the contents of envelopes and parcels. |